What is Allen Bradley Rockwell Automation?

Allen-Bradley is the brand-name of a line of factory automation equipment owned by Rockwell Automation.

What is Rockwell Automation industry?

Rockwell Automation, Inc. is an American provider of industrial automation and digital transformation technologies. Brands include Allen-Bradley, FactoryTalk software and LifecycleIQ Services.

Is Allen Bradley a type of PLC?

Allen‑Bradley® programmable logic controller (PLC) and programmable automation controller (PAC) range from large to small and even micro applications. We offer different controller types and sizes to fit your specific needs.

What is RSLogix used for?

RSLogix is a programming software that is used to program Allen-Bradley PLCs from Rockwell Automation. There are two versions of the RSLogix software available and each version is used to program different Allen-Bradley PLCs. Those two versions are RSLogix 500 and RSLogix 5000.

Is Allen-Bradley the same as Abb?

Swiss-based ABB offers a wide range of control products including PLCs, HMIs and is well known for its robotics offerings. While US based Allen Bradley is one of the most popular companies for control solutions in the US and the world. Both Allen Bradley and ABB offer a full feature PLC line for large control systems.

What is the meaning of industrial automation?

Industrial automation is a set of technologies that uses control systems and devices, such as computer software and robotics, to enable automatic operation of industrial processes and machinery without the need for human operators.

Why choose Rockwell Automation?

Our commitment to integrity, diversity and inclusion helps fuel fresh ideas. We measure ourselves against the best alternatives, cultivating innovation, and increasing the speed of decision-making.

What software does Allen-Bradley PLC use?

Software. ControlLogix and CompactLogix PLCs are both programmed using Studio 5000 Logix Designer. Unlike Connected Components Workbench, Studio 5000 Logix Designer is not free.

What is the difference between Allen-Bradley and Siemens PLC?

Allen-Bradley PLCs require both an Allen-Bradley rack and an AB power supply as well. Siemens, by comparison, can be powered by any 24V DC power supply externally and does not require a rack. Programming – There is considerable difference when programming Allen-Bradley vs Siemens.

What language does Allen-Bradley PLC use?

The four major programming languages in PLC programming are: Ladder Logic. Structure Text. Function block. Sequential Function Chart.

What is the difference between Rockwell and Allen-Bradley?

Stanton Allen, the company eventually became the Allen-Bradley Company. Allen-Bradley is the brand name of several product lines of factory automation equipment and today it’s owned by Rockwell Automation.

Is PLC a software or hardware?

A PLC (Programmable Logic Controller) is made up of both hardware and software components. The PLC hardware refers to the physical components that make up a PLC system. Whereas the PLC software refers to the PLC’s operating system and application program that are stored in the PLC’s memory.

What are 4 PLC languages?

The five most popular PLC Programming Languages are Ladder Logic, Structured Text, Function Block Diagrams, Sequential Flow Charts and Instruction Lists. These methods of programming are available on most platforms. However, certain PLCs will restrict user access to certain languages unless the user pays a premium.

What is RSLogix 500 software used for?

Description. The RSLogix 500 software is a tool to design and implement ladder programs for the Allen-Bradley SLC 500™ and MicroLogix™ family of processors, such as the Programmable Logic Controller (MicroLogix), Model 46964.

How does PLC software work?

PLC programs operate in cycles. First, the PLC detects the state of all input devices that are connected to it. The PLC executes the user-created program, using the state of the inputs to determine the state that the outputs should be changed to. The PLC then changes the output signals to each corresponding device.

Is Allen-Bradley a PLC?

Allen-Bradley PLC Products Currently In Use The company currently provides three basic “Logix” platform families of controllers, MicroLogix PLCs, ControlLogix PLCs and CompactLogix PLCs.

What are the two 2 types of industrial automation?

Industrial processes can be controlled manually, but with industrial automation, machines can be controlled through the use of computers and other electronic devices. There are four main types of industrial automation: fixed automation, programmable automation, flexible automation, and integrated automation.

What is an example of industrial automation?

Robotic and CNC machines are excellent examples of today’s modern automation equipment. Automated devices can control events in a variety of ways and increase efficiency by monitoring data which leads the production line to reduce waste.

What is industrial automation PLC and SCADA?

PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems are essential components of modern industrial automation. They play a crucial role in controlling, monitoring, and optimizing various processes in industries such as manufacturing, energy, and water management.

Who is the competitor of Rockwell Automation?

Rockwell Automation competitors include Schneider Electric, Siemens, GE Digital, Rockwell Collins and Honeywell. Rockwell Automation ranks 2nd in Diversity Score on Comparably vs its competitors.

Is Allen-Bradley still in business?

We are the largest company in the world that is dedicated to industrial automation and information. Across the globe, our flagship Allen‑Bradley® and FactoryTalk® product brands are recognized for excellence.

Is Rockwell Automation an OEM?

The OEM Program, part of the Rockwell Automation PartnerNetwork™, provides Program Participants with an opportunity to collaborate commercially and technically to increase new business opportunities, increase market awareness, expand into new market sectors, and improve technical competency and functional excellence in …

What is PLC programming used for?

A Programmable Logic Controller, or PLC, is a ruggedized computer used for industrial automation. These controllers can automate a specific process, machine function, or even an entire production line.

What is Rockwell Scada software?

SCADA systems which stand for Supervisory Control and Data Acquisition are a network of monitoring and controlling systems which can be found at remote sites like factories or plants. SCADA software are used in a variety of industries to control and monitor equipment and machinery.

What is Rockwell ControlLogix?

Our ControlLogix® control systems use a common control engine with a common development environment to provide high performance in an easy-to-use environment. Tight integration between the programming software, controller, and I/O modules reduces development time and cost at commissioning and during normal operation.

What do Rockwell do?

Rockwell is the largest pure-play industrial automation company helping customers solve the world’s greatest challenges. We meet customers where they are in their journey with our hardware, software and services that harness the potential for every business.

What is Allen Bradley Industrial Automation?

What is Allen-Bradley® Industrial Control?

Who makes Allen-Bradley programmable logic controllers?

When did Allen-Bradley merge with Rockwell Automation?

What makes Allen-Bradley a great company?

Who is Allen-Bradley & FactoryTalk?

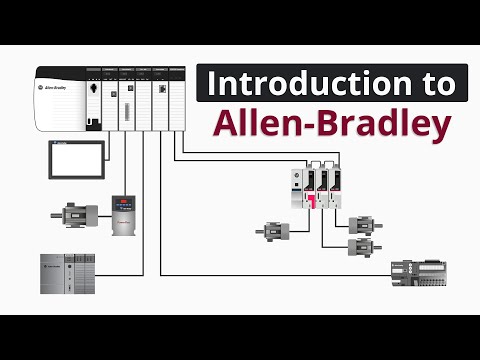

Let’s talk about Allen Bradley Industrial Automation, a big player in the world of manufacturing. Allen Bradley (AB) is actually a brand owned by Rockwell Automation, a massive company that focuses on industrial automation and information solutions. Now, what exactly does industrial automation mean? It’s basically using technology to control and manage manufacturing processes, like making your factory run smoother and smarter.

Imagine a factory that’s like a well-oiled machine, with robots doing tasks, computers monitoring everything, and data flowing everywhere. Allen Bradley plays a huge role in making this happen by providing a wide range of products and services that are the building blocks of this automated world.

Understanding the Basics: Products and Solutions

So, what does Allen Bradley offer? Well, they have a whole bunch of stuff! Think of them as the “one-stop shop” for industrial automation. Here are a few things they’re known for:

1. Programmable Logic Controllers (PLCs): These are like the brains of the operation. They’re basically industrial computers that take instructions from you and then control machines, robots, and all sorts of other equipment. You can tell them what you want, and they’ll make it happen.

2. Human Machine Interfaces (HMIs): These are the touchscreens that let you interact with your automation system. Think of them like a dashboard for your factory. They display information, let you change settings, and even let you troubleshoot problems.

3. Drives and Motors: These are what make your machines move. Allen Bradley makes a wide range of drives that control motors, allowing you to adjust speed, torque, and other parameters.

4. Sensors and Switches: Sensors are the eyes and ears of your automation system. They monitor things like temperature, pressure, and position. Switches let you control things manually. They’re crucial for making sure everything is running smoothly and safely.

5. Networks:Allen Bradley also provides network solutions that allow all your automation components to talk to each other. This makes it possible to share data, control everything from one central location, and manage your operations more efficiently.

6. Software:Allen Bradley has software that helps you design, program, and monitor your automation systems. They have tools for everything from designing your control logic to simulating your system before you build it.

Why Choose Allen Bradley?

You might be wondering, why choose Allen Bradley over other automation companies? Here’s the deal:

Reliability: They’ve been in the game for a long time, and their products are known for being tough and reliable. You can count on them to work in harsh industrial environments.

Scalability:Allen Bradley offers a wide range of products that can be combined to create automation solutions for any size factory. Whether you’re a small startup or a large multinational corporation, they have something for you.

Support:Allen Bradley has a strong support network with experienced engineers and technicians who can help you with everything from installation to troubleshooting.

Compatibility: Their products are designed to work together seamlessly, making it easy to build complex and integrated automation systems.

Industry Standards: They adhere to industry standards, making it easier to integrate their products with other equipment and systems.

Applications of Allen Bradley Industrial Automation

Now, where do we see Allen Bradley in action? This stuff is everywhere! They’re used in industries like:

Manufacturing: From car assembly lines to food processing plants, Allen Bradley automation is crucial for efficient production.

Power Generation: They’re used to control and monitor power plants, ensuring a reliable supply of electricity.

Water and Wastewater Treatment: They’re used to manage and control water treatment processes.

Oil and Gas: They’re used in refineries and drilling rigs to monitor and automate operations.

Building Automation: They’re even used to control and manage building systems like HVAC, lighting, and security.

Allen Bradley is a key player in helping businesses automate their processes and improve efficiency. Their products and services are designed to make factories smarter, more productive, and more reliable.

Benefits of Using Allen Bradley Industrial Automation

Let’s talk about what you get when you choose Allen Bradley for your automation needs:

Increased Efficiency:Allen Bradley solutions can help you optimize your processes, reduce downtime, and increase your overall production output.

Improved Safety: Their products are designed to enhance safety by monitoring processes and detecting potential hazards.

Reduced Costs:Allen Bradley automation can help you cut down on waste, labor costs, and energy consumption.

Better Data Collection: Their systems gather a ton of data, giving you valuable insights into your operations that you can use to make better decisions.

Enhanced Control: You get more control over your processes, allowing you to make adjustments on the fly and respond to changing conditions.

The Future of Allen Bradley Industrial Automation

The world of industrial automation is always evolving. Allen Bradley is constantly innovating and developing new technologies to stay ahead of the curve. Here are some trends we’re seeing:

Internet of Things (IoT):Allen Bradley is integrating IoT technology into its products to enable seamless data sharing and remote monitoring.

Cloud Computing: They’re using cloud platforms to manage and analyze data, providing more powerful insights and analytics.

Artificial Intelligence (AI): Allen Bradley is exploring AI-powered solutions for predictive maintenance, process optimization, and other tasks.

Cybersecurity: Allen Bradley is taking cybersecurity seriously, developing solutions to protect their systems from cyber threats.

As automation becomes more sophisticated, we can expect to see Allen Bradley playing an even bigger role in transforming industries around the world.

FAQs about Allen Bradley Industrial Automation

Let’s answer some common questions people have about Allen Bradley Industrial Automation:

1. What is the difference between Allen Bradley and Rockwell Automation?

Allen Bradley is a brand name owned by Rockwell Automation. Rockwell Automation is the parent company, and Allen Bradley is one of their product lines, focusing on industrial automation. Think of it like this: Rockwell Automation is the big company, and Allen Bradley is the popular brand under their umbrella.

2. Where can I learn more about Allen Bradley products?

You can find tons of information on the Rockwell Automation website, which has detailed product pages, documentation, and support resources.

3. How do I get started with Allen Bradley automation?

You can start by identifying your specific automation needs and then looking at Allen Bradley’s range of products and solutions. Their website has a lot of resources to help you get started, and they also offer training and support services.

4. Is Allen Bradley compatible with other automation systems?

Allen Bradley products are designed to be compatible with other automation systems, but it’s always a good idea to check the specifications before making any decisions.

5. Are Allen Bradley products expensive?

The cost of Allen Bradley products varies depending on the specific product and its features. However, their products are generally considered to be of high quality and value.

6. What are some of the most popular Allen Bradley products?

Some of their most popular products include their PLC family (like the ControlLogix and CompactLogix series), their PanelView HMIs, and their PowerFlex drives.

7. Is there a community for Allen Bradley users?

Yes! You can find active online communities and forums where Allen Bradley users share their experiences, tips, and troubleshooting advice.

8. What are the future trends in Allen Bradley Industrial Automation?

We’re seeing a lot of focus on things like the Internet of Things (IoT), cloud computing, artificial intelligence (AI), and cybersecurity.

9. Can I get training on Allen Bradley products?

Absolutely! Rockwell Automation offers a wide range of training courses, both online and in person, to help you learn how to use their products.

10. How do I contact Allen Bradley for support?

You can contact Rockwell Automation directly through their website or by calling their customer service line.

Allen Bradley is a trusted name in industrial automation, and their products and services are helping to drive innovation and efficiency in countless industries around the world. Whether you’re a seasoned automation expert or just starting out, Allen Bradley has the resources and support you need to succeed.

See more here: What Is The Function Of Plc In Allen Bradley? | What Is Allen Bradley Industrial Automation?

Allen-Bradley Products | Allen-Bradley | US – Rockwell Automation

Allen‑Bradley components, integrated control and information solutions are built for demanding industrial applications. We integrate control and information across the enterprise to make you as productive as possible. Rockwell Automation

Our Company | Rockwell Automation | US

We are the largest company in the world that is dedicated to industrial automation and information. Across the globe, our flagship Allen-Bradley® and FactoryTalk® product brands are recognized for Rockwell Automation

Industrial Control Products | Allen-Bradley | US – Rockwell

industrial automation. The Allen-Bradley portfolio of smart devices represents the cutting edge of industrial automation technology. These intelligent devices leverage advanced Rockwell Automation

Understanding Allen-Bradley – Inductive Automation Help Center

What is Allen-Bradley? Allen-Bradley is the vendor name for a popular brand of PLC products owned by Rockwell Automation. Such PLCs rely on the connection-based, Inductive Automation

Introduction to Automation – Rockwell Automation

After completing this course, you should have a broad and fundamental understanding of industrial automation. Topics range from an overview of common automation rockwellautomation.com

How an Industrial Control System Delivers – Rockwell Automation

The Allen-Bradley® ASEM 6300 family of open architecture PCs, thin clients and monitors is the latest in a long line of revolutionary breakthroughs that have helped our clients win rockwellautomation.com

An Introduction to Allen-Bradley PLC | Rockwell Automation

Allen-Bradley is the brand name of several product lines of factory automation equipment and today it’s owned by Rockwell Automation. Allen-Bradley RealPars

Allen Bradley vs Siemens: What’s the difference

Two such PLCs, Rockwell’s Allen-Bradley and Siemens are two of the world’s most widely used PLCs – and while each device is undeniably an industry staple there are a number of key differences PLC Technician

See more new information: v1.vietmasks.com

Link to this article: What is Allen Bradley Industrial Automation?.

See more articles in the same category here: v1.vietmasks.com/category/automation-technology